Introduction to Custom Crawler Frames

Welcome to the world of custom crawler frames! If you're in need of a heavy-duty, reliable frame for your crawler equipment, then you've come to the right place. In this ultimate guide, we will take you on an exciting journey through the process of manufacturing custom crawler frames. From understanding the benefits of customization to choosing the perfect manufacturer, we've got you covered. So grab a and get ready to dive into the fascinating world of custom crawler frame manufacturing!

The Benefits of a Customized Frame

When it comes to crawler frames, one size does not fit all. That's why opting for a customized frame can bring numerous benefits to your project.

A custom crawler frame allows you to tailor the design and specifications according to your specific needs. Whether you require additional strength, increased load capacity, or unique dimensions, a customized frame can be built to meet these requirements precisely.

Moreover, with a custom crawler frame, you have the freedom to choose from various materials that best suit your application. From lightweight aluminum alloy for enhanced mobility, to durable steel for heavy-duty projects, the options are endless.

Another advantage of customization is improved efficiency and performance. By optimizing the design based on your specific needs and preferences, you can achieve better stability and maneuverability in challenging terrains.

Additionally, customization enables easy integration of additional components such as motors or hydraulic systems into the frame structure. This ensures seamless operation of your machinery without compromising on safety or functionality.

Furthermore, investing in a custom crawler frame demonstrates foresight and innovation in your industry. It sets you apart from competitors by showcasing your commitment towards delivering high-quality solutions tailored specifically for each project.

In conclusion, opting for a customized crawler frame brings several benefits including enhanced design flexibility, improved performance and efficiency as well as setting yourself apart in an increasingly competitive market

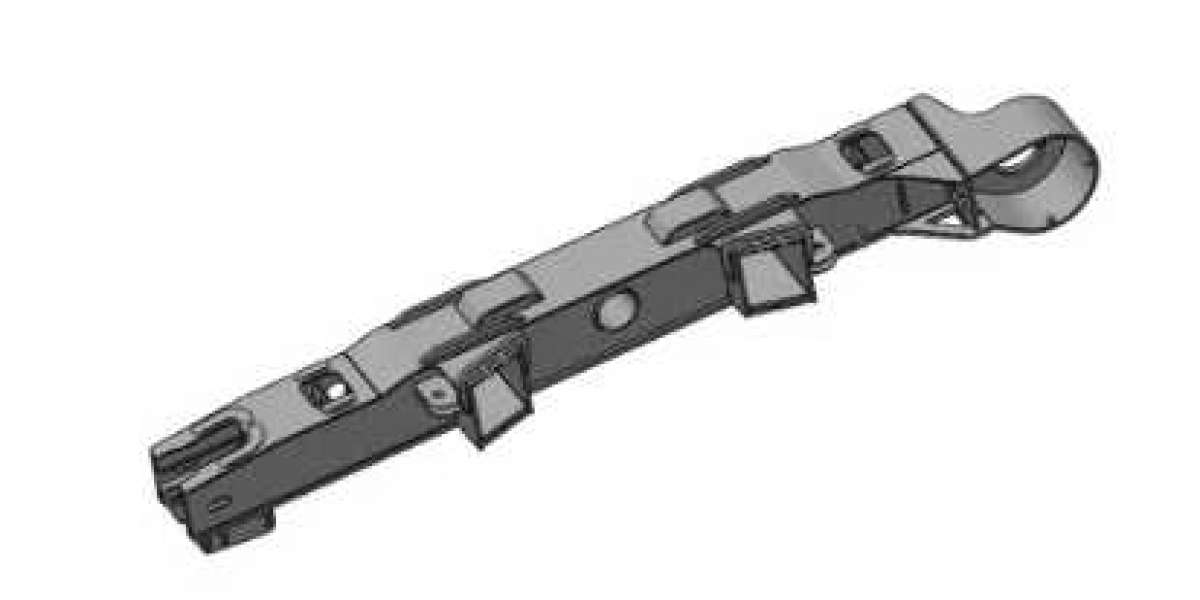

The Process of Manufacturing a Custom Crawler Frame

The process of manufacturing a custom crawler frame involves several steps to ensure the final product meets all the required specifications and standards. It begins with detailed design and engineering, where the specific requirements of the crawler frame are carefully considered.

Once the design is finalized, it moves on to material selection. Custom crawler frames can be made from various materials such as steel, aluminum, or composite materials. The choice of material depends on factors like load capacity, durability, and weight limitations.

Next comes fabrication, where skilled technicians use advanced machinery and techniques to shape and assemble the components of the crawler frame. This includes cutting, welding, bending, and surface finishing processes.

Quality control is an essential part of the manufacturing process. Each stage undergoes rigorous inspection to ensure that all dimensions are accurate and that there are no structural defects or weaknesses in the finished product.

After fabrication is complete, additional customization options may be added based on customer requirements. This could include features like mounting brackets for equipment attachments or specialized paint coatings for enhanced corrosion resistance.

Before delivery, thorough testing ensures that the custom crawler frame performs optimally under different operating conditions. This includes assessing its strength under heavy loads as well as checking for any potential issues in functionality or stability.

In conclusion, understanding how a custom crawler frame is manufactured provides valuable insight into why it's important to choose a reputable manufacturer who employs meticulous processes at every stage - from initial design through to final testing.

The Different Types of Materials Used in Custom Crawler Frames

When it comes to manufacturing custom crawler frames, choosing the right materials is crucial. The type of material used will determine the strength, durability, and overall performance of the frame. There are several different types of materials that can be used in custom crawler frame manufacturing.

One common material used in custom crawler frames is steel. Steel is known for its exceptional strength and ability to withstand heavy loads and rugged terrain. It is a popular choice among manufacturers due to its durability and long lifespan.

Another material often used in custom crawler frames is aluminum. Aluminum offers similar strength to steel but with a lighter weight, making it ideal for applications where weight reduction is critical. It also has excellent corrosion resistance properties, which makes it suitable for use in wet or corrosive environments.

For specialized applications that require even greater strength-to-weight ratio, manufacturers may opt for composite materials such as carbon fiber reinforced polymers (CFRP). These materials offer high tensile strength while being significantly lighter than both steel and aluminum.

In addition to these primary materials, other components like bolts, fasteners, and bushings are typically made from stainless steel or other corrosion-resistant alloys to ensure longevity and reliability.

Choosing the right material ultimately depends on factors such as load capacity requirements, environmental conditions, budget constraints, and specific application needs. Working closely with an experienced manufacturer who understands these considerations can help you select the most suitable material for your custom crawler frame project.

Remember that selecting the appropriate material plays a vital role in determining the overall performance and lifespan of your custom crawler frame – so take your time evaluating your options before making a decision!

How to Choose the Right Custom Crawler Frame Manufacturer

When it comes to choosing the right custom crawler frame manufacturer, there are several factors that you should consider. First and foremost, you need to ensure that the manufacturer has a solid reputation in the industry. Look for companies with years of experience and positive customer reviews.

Next, take a look at their portfolio of work. Do they have experience manufacturing crawler frames similar to what you are looking for? It's important to find a manufacturer who understands your specific needs and can deliver high-quality, customized products.

Another key consideration is their manufacturing capabilities. Do they have state-of-the-art equipment and facilities? Are they able to handle large-scale production if necessary? You want to choose a manufacturer who has the resources and expertise to meet your demands.

Price is also an important factor when choosing a custom crawler frame manufacturer. While cost shouldn't be the sole determining factor, it's important to find a provider who offers competitive pricing without compromising on quality.

Don't forget about customer service. A reliable manufacturer should be responsive, communicative, and willing to address any concerns or questions you may have throughout the manufacturing process.

By carefully considering these factors, you can choose the right custom crawler frame manufacturer that will meet your unique requirements and deliver top-notch products tailored specifically for your needs

Conclusion

In this ultimate guide to custom crawler frame manufacturing, we have explored the importance and benefits of opting for a customized frame for your crawler equipment. We have also delved into the process of manufacturing these frames, the different materials used, and how to choose the right manufacturer.

By investing in a custom crawler frame, you can ensure that your equipment is tailored to meet your specific needs and requirements. Whether you need increased stability, improved maneuverability, or enhanced durability, a customized frame can provide you with the solution.

When selecting a custom crawler frame manufacturer, it is crucial to consider their expertise in design and engineering. Look for companies like Hengli supplier who have extensive experience in producing high-quality frames that are built to last.

Remember that choosing the right material for your custom crawler frame is equally important. Depending on factors such as load capacity, environmental conditions, there are various options available including steel alloys or advanced composite materials.

A well-designed and properly manufactured custom crawler frame will not only enhance the performance of your equipment but also improve safety standards on job sites. It will increase productivity by minimizing downtime due to breakdowns or inefficiencies caused by subpar frames.

So if you're in need of a reliable and efficient custom crawler frame solution for your machinery, consider working with an experienced manufacturer like Hengli supplier who can deliver superior products tailored specifically to meet your unique requirements.

With their expertise and commitment to quality craftsmanship, they can help take your crawler equipment's performance to new heights while ensuring optimal functionality across various applications.