"High Temperature Gaskets Market Size, Share, and Trends Analysis Report—Industry Overview and Forecast to 2032

The Heat-Resistant Seals Market is experiencing rapid expansion, driven by rising consumer demand, technological progress, and continuous industry innovation. Leading market research firms report that businesses in the Industrial High-Temp Gaskets Market are increasingly focusing on digital transformation, advanced product development, and data-driven strategies to maintain competitiveness. With growing investments in automation and operational efficiency, the Fireproof Sealing Solutions Market is evolving to align with shifting customer preferences. Industry leaders are implementing research-backed approaches to solidify their market presence, ensuring long-term stability. Reports indicate that Thermal Insulation Gaskets Market major players are adopting cutting-edge technologies to improve efficiency and enhance customer experiences in the High-Pressure Heat Gaskets Market.

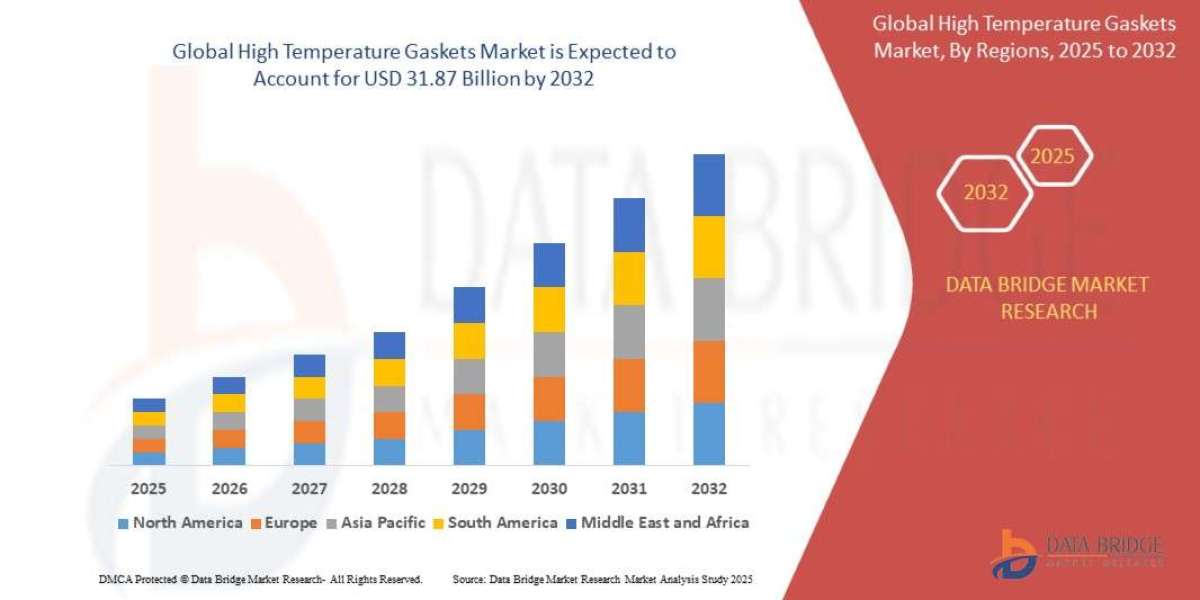

The High Temperature Gaskets Market is poised for significant growth, with a market outlook highlighting substantial growth potential driven by emerging opportunities in key sectors. This report provides strategic insights, demand dynamics, and revenue projections, offering a comprehensive view of the future landscape, technology disruptions, and adoption trends shaping the industry’s ecosystem evaluation. According to Data Bridge Market Research The global high temperature gaskets market size was valued at USD 21.90 billion in 2024 and is projected to reach USD 31.87 billion by 2032, with a CAGR of 4.80% during the forecast period of 2025 to 2032.

Our approach to analyzing the Engine Heat Gaskets Market goes beyond surface-level data. We delve into the underlying drivers, examining the interplay of various factors that shape the Aerospace High-Temp Seals Market. This involves understanding the perspectives of key stakeholders and identifying the emerging dynamics within the Heavy-Duty Heat-Resistant Gaskets Market. By focusing on qualitative insights alongside quantitative data, we provide a holistic view of the market. We are committed to delivering actionable intelligence that empowers businesses to make informed choices within the Extreme Environment Sealing Market. The landscape of the market is ever-changing. We seek to provide clarity about the Advanced Thermal Sealing Solutions Market.

Our comprehensive High Temperature Gaskets Market report is ready with the latest trends, growth opportunities, and strategic analysis. https://www.databridgemarketresearch.com/reports/global-high-temperature-gaskets-market

**Segments**

- Based on material type, the high temperature gaskets market can be segmented into graphite, fluorocarbon, ceramic, fiberglass, and others. Graphite gaskets are known for their thermal stability and chemical resistance, making them a popular choice in various industries. Fluorocarbon gaskets offer excellent sealing properties and are widely used in applications where resistance to harsh chemicals is required. Ceramic gaskets are valued for their high-temperature resistance and durability, ideal for extreme operating conditions. Fiberglass gaskets are flexible and lightweight, making them suitable for sealing applications in industries such as automotive and aerospace.

- By product type, the market can be categorized into spiral wound gaskets, Kammprofile gaskets, ring gaskets, corrugated gaskets, and others. Spiral wound gaskets are popular due to their ability to withstand high pressure and temperature fluctuations. Kammprofile gaskets provide a reliable seal in challenging environments, thanks to their metal core with a flexible graphite or PTFE facing. Ring gaskets are versatile and widely used in various industries for sealing purposes. Corrugated gaskets offer enhanced flexibility and are effective in sealing irregular flange surfaces.

- On the basis of end-use industry, the high temperature gaskets market can be segmented into oil & gas, chemical processing, power generation, automotive, aerospace, and others. The oil & gas industry extensively relies on high temperature gaskets for sealing pipelines, valves, and flanges in harsh operating conditions. Chemical processing plants utilize these gaskets to prevent leakage and ensure safety in corrosive environments. In the automotive sector, high temperature gaskets are essential for engines, exhaust systems, and other critical components. Aerospace applications demand gaskets that can withstand extreme temperatures and pressure differentials.

**Market Players**

- Some of the key players in the global high temperature gaskets market include Garlock Sealing Technologies, Flexitallic Group Inc., Teadit Group, Freudenberg Sealing Technologies, Lamons, Spetech, W. L. Gore & Associates, Inc., Mercer Rubber Company, and Goodrich Gasket Pvt. Ltd. These companies focus on product innovation, strategic collaborations, and expanding their regional presence to gain a competitive edge in the market. By offering a diverse range of high-quality gaskets tailored to specific industry requirements, these market players cater to a wide range of applications and ensure customer satisfaction.

https://www.databridgemarketresearch.com/reports/global-high-temperature-gaskets-market The global high temperature gaskets market is witnessing significant growth driven by increasing demand from various end-use industries such as oil & gas, chemical processing, power generation, automotive, and aerospace. High temperature gaskets play a crucial role in ensuring reliable sealing solutions in challenging environments characterized by extreme temperatures, pressure differentials, and corrosive substances. Graphite gaskets, fluorocarbon gaskets, ceramic gaskets, and fiberglass gaskets are among the key material types used in high temperature applications, each offering unique properties to meet specific industry requirements. The versatility and effectiveness of spiral wound gaskets, Kammprofile gaskets, ring gaskets, and corrugated gaskets make them popular choices for sealing applications across different sectors.

Market players like Garlock Sealing Technologies, Flexitallic Group Inc., and Freudenberg Sealing Technologies are leading the global high temperature gaskets market through innovative product offerings, strategic partnerships, and geographical expansion. These companies focus on developing gaskets that can withstand extreme conditions while providing superior sealing performance, meeting the stringent requirements of industries like oil & gas and aerospace. With a strong emphasis on customer satisfaction, these market players aim to cater to a diverse range of applications by offering high-quality gaskets tailored to specific industry needs.

In the high temperature gaskets market, technological advancements and material innovations are driving the development of gaskets with enhanced thermal stability, chemical resistance, and sealing capabilities. The adoption of advanced manufacturing processes and materials is enabling manufacturers to meet the evolving demands of industries seeking reliable sealing solutions for critical applications. As the need for high temperature gaskets continues to grow across various sectors, market players are investing in research and development to stay ahead of the competition and address emerging challenges in sealing technology.

Furthermore, the increasing focus on sustainability and environmental regulations is influencing the design and production of high temperature gaskets to meet stringent compliance standards. Companies in the market are exploring eco-friendly materials and manufacturing practices to reduce their carbon footprint and support sustainable development goals. By incorporating green initiatives into their operations, market players are not only meeting regulatory requirements but also appealing to environmentally conscious customers looking for sustainable sealing solutions.

Overall, the global high temperature gaskets market is poised for steady growth fueled by technological advancements, expanding end-use industries, and the continuous drive for innovation among key market players. With a strong emphasis on quality, performance, and sustainability, the market is set to witness further developments in product offerings and applications, catering to the diverse needs of industries requiring reliable high temperature sealing solutions.**Segments**

Global High Temperature Gaskets Market Segmentation:

- **Material**: The high temperature gaskets market can be segmented by material into Graphite, Fluorosilicone, Fiberglass, Ceramic, Mica, Teflon, SiliconStainless Steel & alloy, UHT Liquid Gasket Materials, and Others. Each material offers unique properties such as thermal stability, chemical resistance, flexibility, and durability to cater to specific industry requirements.

- **Product**: Categorized as Metallic, Semi-Metallic, Non-Metallic, and UHT Liquid Gaskets, different product types like spiral wound, Kammprofile, double-jacketed, fishbone, and others provide varying sealing capabilities suitable for different applications.

- **Design**: The design segmentation includes spiral wound, Kammprofile, double-jacketed, fishbone, and others, offering versatility and effectiveness in sealing applications.

- **Application**: Focused in industries such as Power Generation, Oil & Gas, Chemical Processing, Primary Metals, Transportation, and others, high temperature gaskets play a crucial role in ensuring reliable sealing solutions in environments with extreme temperatures and pressures.

**Market Players**

- Henkel Adhesives Technologies India Private Limited (Germany)

- ThreeBond Holdings Co., Ltd. (Japan)

- Lamons (U.S.)

- Enpro Inc. (U.S.)

- TEADIT (U.S.)

- 3M (U.S.)

- Flexitallic US LLC (U.K.)

- Gasket Resources, Inc. (U.S.)

- SPETECH (Poland)

- Premier Seals (India)

- National Engineering Products, Inc. (U.S.)

- Whitmore Manufacturing, LLC. (U.S.)

- H.B. Fuller Company (Germany)

- A.I. Schulze Chemotecnische Fabrik e.K. (Germany)

- IGS Industries (U.S.)

- A.W. Chesterton Company (U.S.)

- Hennig Gasket & Seals Inc. (U.S.)

- Advanced Sealing, Inc. (U.S.)

- Whitmore Manufacturing LLC. (U.S.)

- DURLON (U.S.)

The global high temperature gaskets market is witnessing growth due to the increasing demand from key industries like oil & gas, chemical processing, power generation, automotive, and aerospace. Market players like Henkel Adhesives Technologies, ThreeBond Holdings, and Lamons are at the forefront, focusing on innovation, partnerships, and geographical expansion to remain competitive. Technological advancements drive the development of gaskets with enhanced properties, meeting the demands of challenging environments. Addressing sustainability concerns, companies are exploring eco-friendly materials and manufacturing practices to align with environmental regulations and customer preferences. With a commitment to quality, performance, and sustainability, the market is poised for further growth and development in meeting industry requirements for reliable high temperature sealing solutions.

The market is highly fragmented, with a mix of global and regional players competing for market share. To Learn More About the Global Trends Impacting the Future of Top 10 Companies in High Temperature Gaskets Market : https://www.databridgemarketresearch.com/reports/global-high-temperature-gaskets-market/companies

Key Questions Answered by the Global High Temperature Gaskets Market Report:

- How is consumer demand shifting in response to market trends in the High Temperature Gaskets Market?

- What are the investment opportunities in the High Temperature Gaskets Market?

- How will automation and AI integration impact High Temperature Gaskets Market growth?

- What are the key marketing strategies used by leading companies in the High Temperature Gaskets Market?

- What is the Size, Share, and Scope of the High Temperature Gaskets Market?

- What is the current and projected Demand, Growth, and Value of the High Temperature Gaskets Market?

- What are the major Opportunities available in the High Temperature Gaskets Market?

- What are the key Industry Statistics and Industry Trends shaping the High Temperature Gaskets Market?

- How does the Industry Share of major players compare in the High Temperature Gaskets Market?

- What is the Revenue Analysis of the High Temperature Gaskets Market, and how is it expected to change

- How will competitive strategies evolve, and what impact will they have on market outlook?

Browse More Reports:

https://www.databridgemarketresearch.com/reports/global-ice-detection-system-market

https://www.databridgemarketresearch.com/reports/global-oil-and-gas-cloud-applications-market

https://www.databridgemarketresearch.com/reports/europe-chromatography-food-testing-market

https://www.databridgemarketresearch.com/reports/global-voice-termination-market

https://www.databridgemarketresearch.com/reports/global-concentrated-photovoltaic-market

Data Bridge Market Research:

☎ Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC: +653 1251 982

✉ Email: corporatesales@databridgemarketresearch.com

Tag

High Temperature Gaskets Market Size, High Temperature Gaskets Market Share, High Temperature Gaskets Market Trend, High Temperature Gaskets Market Analysis, High Temperature Gaskets Market Report, High Temperature Gaskets Market Growth, Latest Developments in High Temperature Gaskets Market, High Temperature Gaskets Market Industry Analysis, High Temperature Gaskets Market Key Players, High Temperature Gaskets Market Demand Analysis"