Graphene polystyrene insulation sandwich panel (GPI) refers to a rigid foam with closed-cell structure formed by extrusion and foaming, with polystyrene resin or its copolymer as the main component, adding graphene and other additives. Plate products; graphene polystyrene insulation sandwich panel (GPI) is based on graphene extruded polystyrene foam as the core material, used in large industrial plants, warehouses, gymnasiums, supermarkets, hospitals, cold storage, mobile rooms, buildings Material storage, clean workshop and other places.

Due to its special structure, graphite has the following special properties:

1) High temperature resistant type: The melting point of graphite is 3850±50°C, and the boiling point is 4250°C. Even if it is burnt by an ultra-high temperature arc, the weight loss is very small, and the thermal expansion coefficient is also small. The strength of graphite increases with the increase of temperature, and at 2000°C, the strength of graphite doubles.

2) Electrical and thermal conductivity: the conductivity of graphite is one hundred times higher than that of ordinary non-metallic minerals. Thermal conductivity exceeds that of metal materials such as steel, iron, and lead. Thermal conductivity decreases with increasing temperature, and even at extremely high temperatures, graphite acts as a thermal insulator.

3) Lubricity: The lubricating performance of graphite depends on the size of graphite flakes. The larger the flakes, the smaller the friction coefficient and the better the lubricating performance.

4) Chemical stability: Graphite has good chemical stability at room temperature, and is resistant to acid, alkali and organic solvents. 5) Plasticity: Graphite has good toughness and can be formed into very thin flakes.

5) Thermal shock resistance: When graphite is used at room temperature, it can withstand drastic changes in temperature without damage. When the temperature changes suddenly, the volume of graphite does not change much, and no cracks will occur.

Graphene polystyrene insulation sandwich panel (GPI) is a new type of thermal insulation material, which generates heat from the whole panel, and the overall electrothermal conversion rate is above 98%, which reduces the loss of electricity, and the heating speed is relatively fast Yes, generally it takes about 5 minutes to make the room temperature reach above 18 degrees Celsius, which can save electricity bills very well.

Characteristics of graphene polystyrene insulation sandwich panel (GPI):

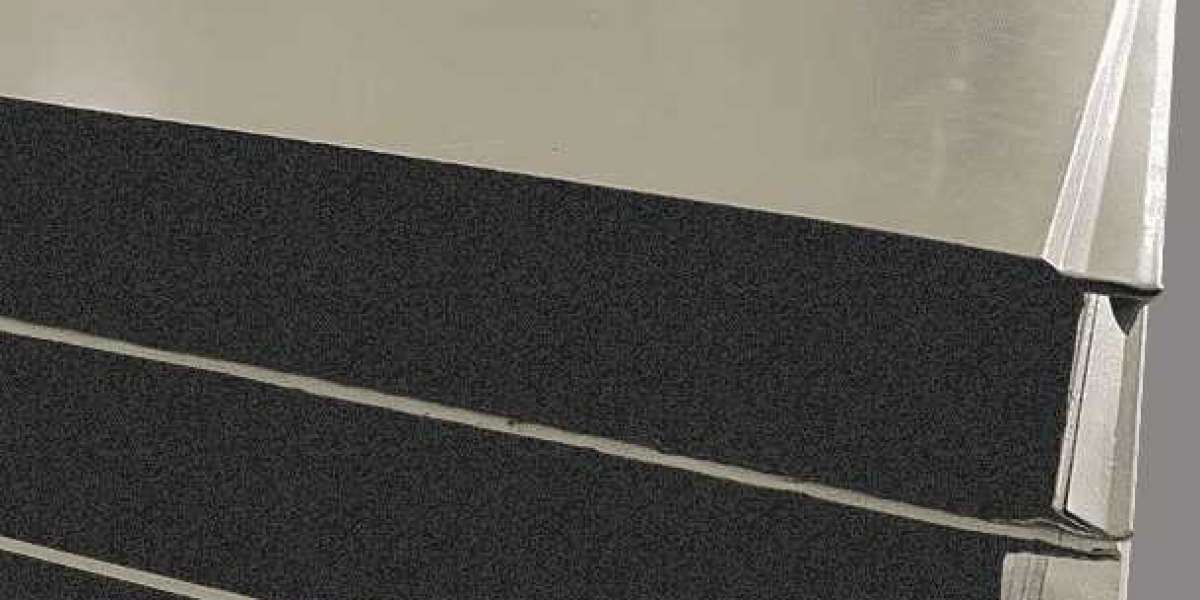

Graphene polystyrene insulation sandwich panel (GPI) is composed of two layers of formed metal panels (or other material panels) and graphite extruded polystyrene foam core. These finished sandwich panels are easy to install, lightweight and efficient. The filling system also uses a closed-cell molecular structure, which can prevent condensation of water vapor. The forming of the outer steel plate fully considers the structure and strength requirements, and takes into account the aesthetics, and the inner surface is formed into a flat plate to meet various needs.

1. Graphite extruded polystyrene foam material is an upgraded product of heat insulation effect of traditional extruded polystyrene foam material. The added graphite component improves the heat insulation effect by about 15% and enhances the strength of the board. The cost has not increased significantly, and replacing the currently best but expensive polyurethane foam material can fully reduce the structural cost. The compressive strength of the graphite extruded polystyrene foam core material is greater than 300 KPa, and the thermal conductivity of the core material is less than or equal to 0.024 W/(m•k). The strength and thermal insulation effect of the board are better than most thermal insulation materials.

2. The main application field of GPI is cold storage. The better the long-term effect of the cold storage design insulation scheme, the lower the energy consumption and the lower the overall cost. The relative humidity of cold storage is mostly above 85%, so the insulation effect of insulation materials under high humidity is very important. GPI's core material, graphite extruded polystyrene foam, has a closed cell rate greater than or equal to 99%, a water vapor transmission coefficient of less than 3.0ng/(m•s•Pa), and a hydrophilic polar group of polyurethane In contrast, its molecular chain is entirely composed of hydrophobic polyolefin, and its water absorption rate is less than 1.0%. Therefore, under low temperature and humid environment, GPI has excellent heat preservation, moisture-proof and mildew-proof characteristics.

3. Quick installation, light weight, plug-in, installation and free cutting, determine its easy installation, which can improve efficiency and save construction period.

4. Fire prevention. The surface material and insulation material of graphene polystyrene insulation sandwich panel (GPI) are non-combustible or flame-retardant materials, which can meet the fire protection design requirements.

About Feininger

Feininger, a leading manufacturer in China, specializes in the continuous production of Graphene Polystyrene Insulation Sandwich Panels. With a steadfast commitment to quality, we have established ourselves as a reliable and reputable source for this innovative construction material.

Our Graphene Polystyrene Insulation Sandwich Panels are designed to deliver exceptional thermal performance, providing superior insulation properties for a wide range of applications. These panels are engineered to meet the highest industry standards, ensuring both energy efficiency and cost-effectiveness in building projects.

What sets us apart is our unwavering dedication to product quality and consistency. FEININGER employs state-of-the-art manufacturing processes and utilizes top-grade materials to produce panels that are not only thermally efficient but also durable and long-lasting. We understand the importance of delivering products that stand the test of time, and we take pride in our ability to do just that.

Our team of experts is committed to working closely with clients to tailor our Graphene Polystyrene Insulation Sandwich Panels to their specific needs and project requirements. Whether you're constructing residential buildings, commercial structures, or industrial facilities, our panels are designed to enhance energy efficiency, reduce carbon footprints, and contribute to a sustainable future.

At FEININGER, we are not just manufacturers; we are partners in your success. We believe in building relationships with our customers based on trust, reliability, and a shared commitment to excellence. When you choose our Graphene Polystyrene Insulation Sandwich Panels, you're choosing a product that delivers on its promises and a company that stands by its word.

Choose FEININGER for the insulation solution that combines innovation, quality, and sustainability. Experience the future of construction materials with our Graphene Polystyrene Insulation Sandwich Panels.