If you're tackling a DIY project and thinking about using plumbing solder for electronics, it might seem convenient—but it’s actually a bad idea. While both plumbing and electronics solder are used to bond metal, they serve very different purposes and have distinct chemical properties.

What Is Plumbing Solder?

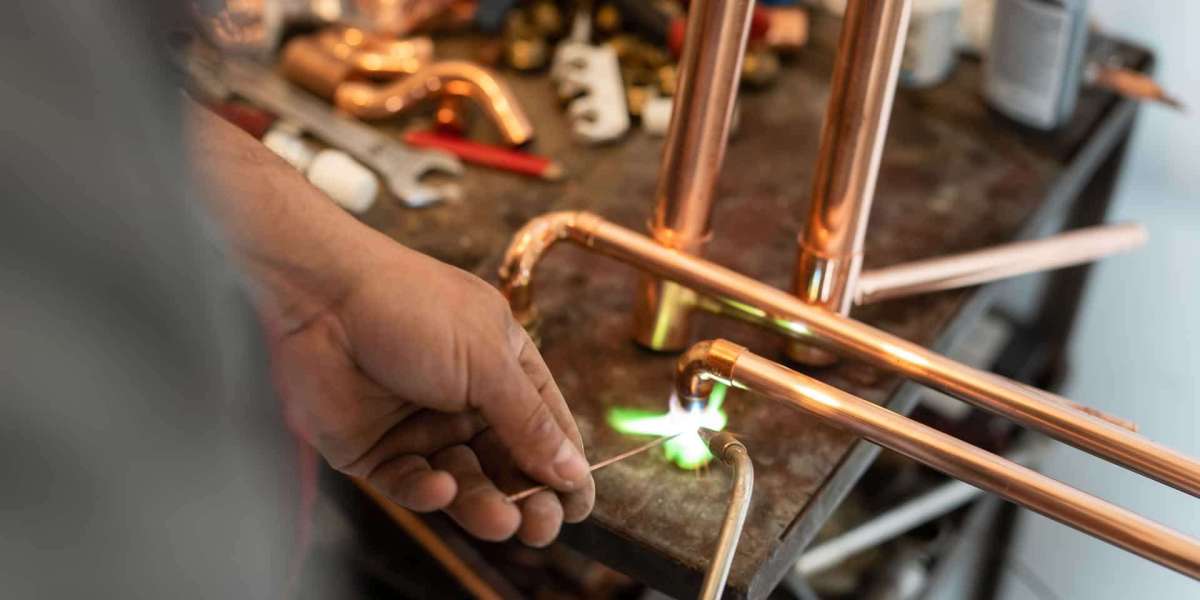

Plumbing solder is typically used for joining copper pipes and fittings in plumbing systems. It's designed to form a strong, leak-proof connection that can handle water pressure and temperature changes. This type of solder usually includes acid-based flux to help clean metal surfaces and create a solid bond.

Because of its high melting point and corrosive flux, plumbing solder is not safe for electronics.

What Makes Electronics Solder Different?

Electronics solder is made for creating electrical connections—for example, bonding wires to circuit boards or connecting components inside a device. This type of solder typically includes rosin-based flux, which is non-corrosive and safe for fragile electronic parts.

Electronics solder also melts at a lower temperature, which is important for protecting delicate components from heat damage.

Plumbing Solder vs. Electronics Solder: Key Differences

Let’s break down why these two types of solder aren’t interchangeable:

? 1. Composition

Plumbing solder: Often a blend of tin, silver, and copper. It uses acidic flux, which is effective for plumbing but corrosive to electronics.

Electronics solder: Typically made from tin and lead, or a lead-free mix with silver and copper. It includes rosin-core flux, which is much gentler on components.

? 2. Flux Type

Plumbing flux: Acid-based, designed to remove tough oxidation from pipes—but it can destroy electronic parts.

Electronics flux: Rosin-based, safe for circuits and doesn’t cause corrosion.

? 3. Melting Point

Plumbing solder: Requires higher heat (around 360°F to 460°F / 182°C–238°C).

Electronics solder: Melts at a lower temperature (370°F / 188°C for leaded solder).

? 4. Intended Use

Plumbing solder: Built for strength, water resistance, and durability.

Electronics solder: Designed for conductivity, clean connections, and component safety.

Why Plumbing Solder Shouldn’t Be Used on Electronics

? 1. Corrosive Flux Damages Circuits

Plumbing solder uses flux that can:

Eat away at circuit traces

Leave conductive residue that causes shorts

Lead to long-term component failure

? 2. Heat Can Damage Components

Because plumbing solder needs high heat to melt, it can:

Overheat or burn sensitive components

Melt plastic parts on PCBs

Cause weak or unreliable solder joints

? 3. Lead Safety Issues

Many older plumbing solders contain high levels of lead, which is harmful. Electronics-grade solder (even if leaded) is regulated for safety, but plumbing solder isn't suitable for tech-related use due to health and functionality concerns.

What Kind of Solder Should You Use for Electronics?

If you're working on any kind of electronic project, these are the best options:

✅ 1. Lead-Based Electronics Solder (Sn60Pb40)

Melts at: 370°F (188°C)

Pros: Smooth flow, easy to work with, reliable

Best for: DIY repairs, hobby projects, and older electronics

✅ 2. Lead-Free Electronics Solder (Sn96.5Ag3.0Cu0.5)

Melts at: 420°F (215°C)

Pros: Eco-friendly and RoHS-compliant

Best for: Commercial electronics, green builds

✅ 3. Silver-Bearing Solder

Pros: Extra strength and conductivity

Best for: High-performance or mission-critical electronics (e.g., medical or aerospace)

How to Solder Electronics the Right Way

? Tools You'll Need:

Soldering iron (15W–60W)

Rosin-core electronics solder

Soldering stand or helping hands

Tip cleaner (sponge or brass wool)

Desoldering pump or wick

?️ Quick Steps:

Clean and position your components.

Heat the joint, not the solder.

Apply solder to the heated area so it flows naturally.

Let it cool and inspect the joint (it should be shiny and solid).

Test it using a multimeter for continuity.

Conclusion: Keep Plumbing Solder Away from Electronics

While plumbing solder works great for copper pipes and water systems, it should never be used on electronics. Its acidic flux, high heat requirement, and non-conductive properties make it a risky and ineffective option for soldering circuits.

If you're working on electronics, always use rosin-core electronics solder to ensure a clean, safe, and durable connection.

Need Professional Help?

For electrical work, HVAC issues, or expert advice on safe soldering practices, reach out to Gleason Heating and Air Conditioning. We’re here to help with professional-grade solutions and reliable service.